...

...

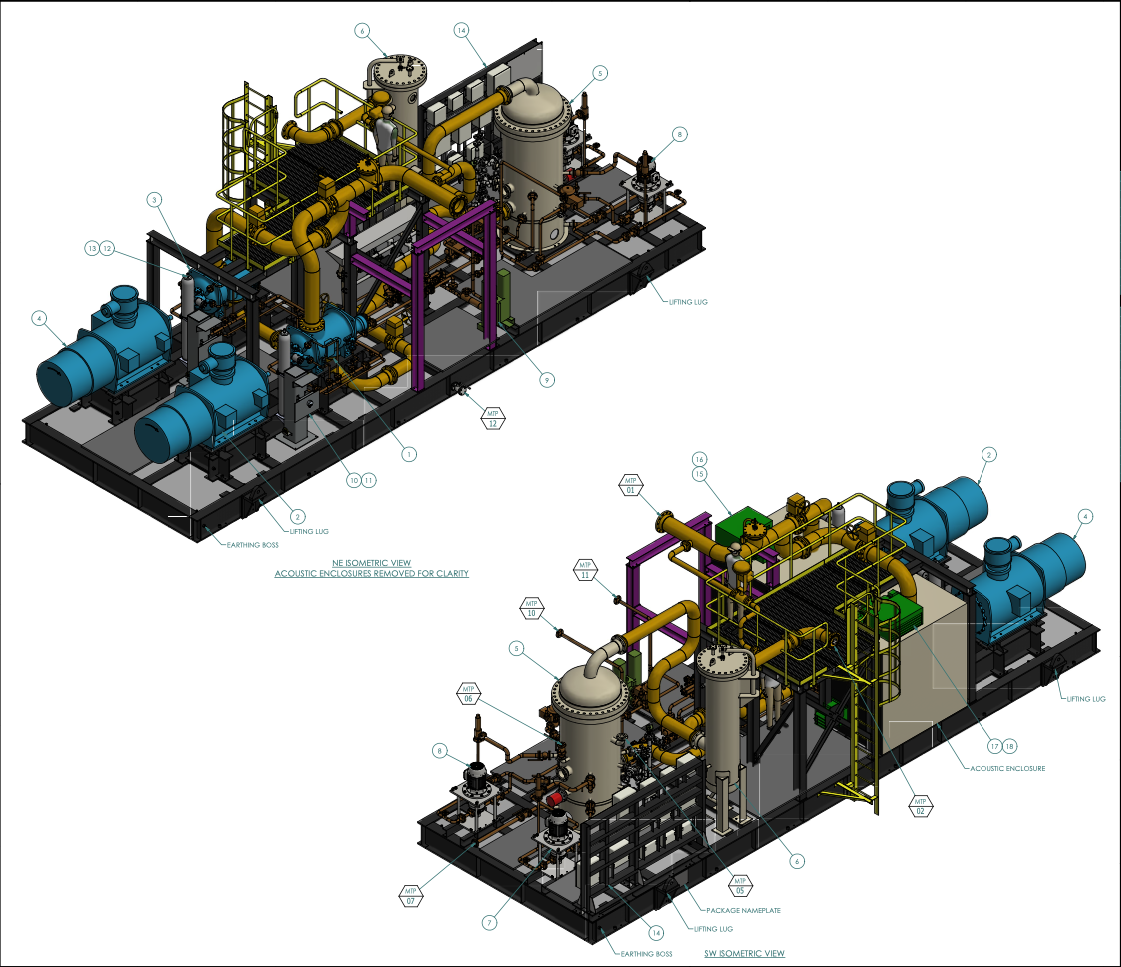

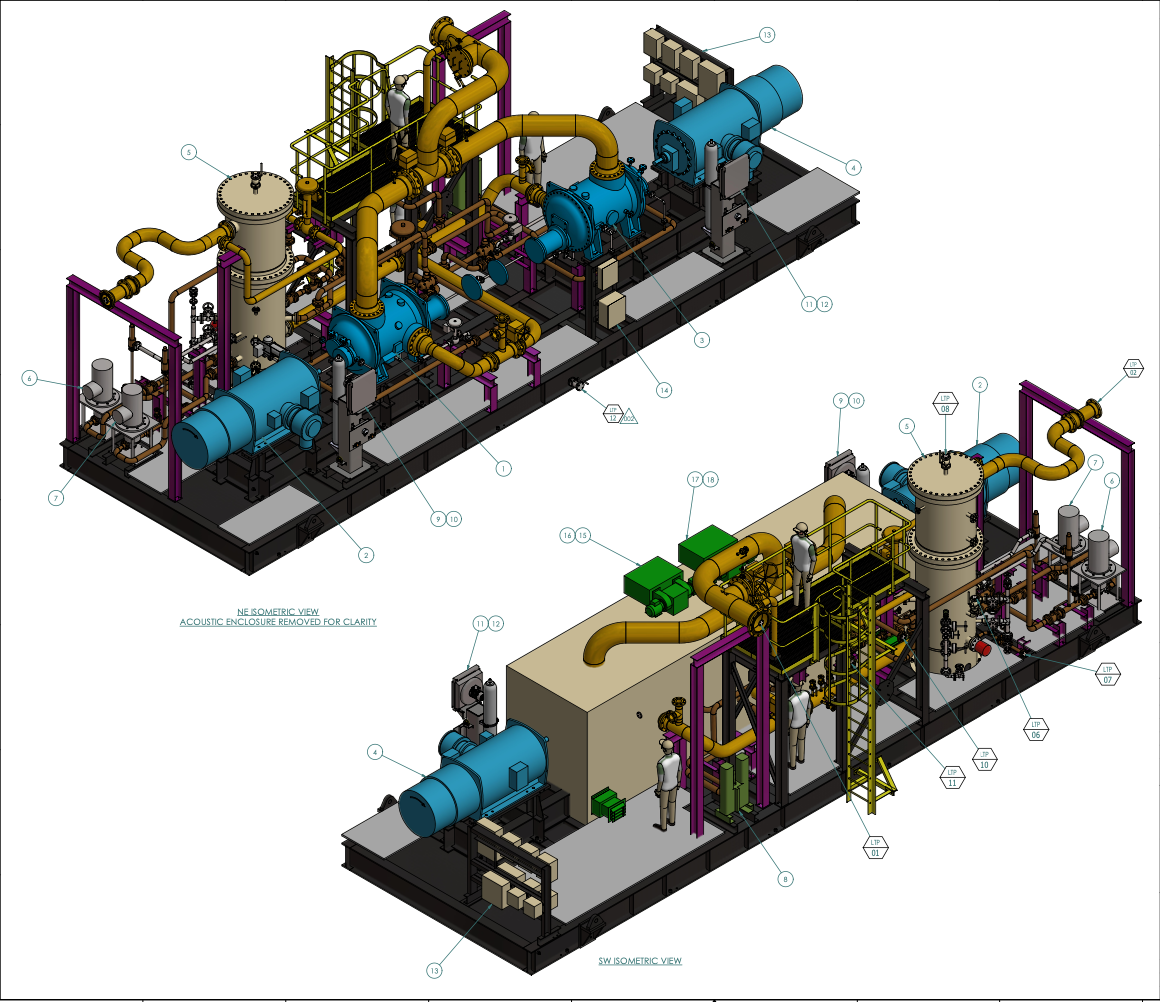

This project involved designing, supplying, installing, and commissioning

a range of industrial components. These components include a turbine,

compressor, heat exchanger, scrubbers, piping, fittings, flanges, seal gas

compressor, fire fighting system, MV/LV switchgears, MCC panels, DCS, and

field instrumentation. These components have now been successfully

installed and commissioned as part of the project. To ensure the project's

success, the following measures were taken:

- A feasibility study was conducted to determine the project's viability.

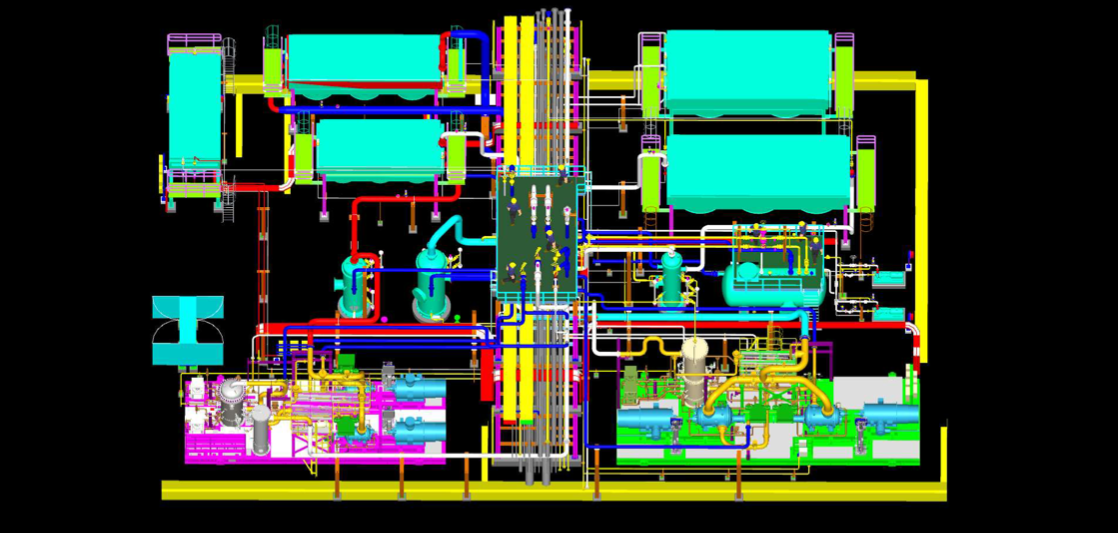

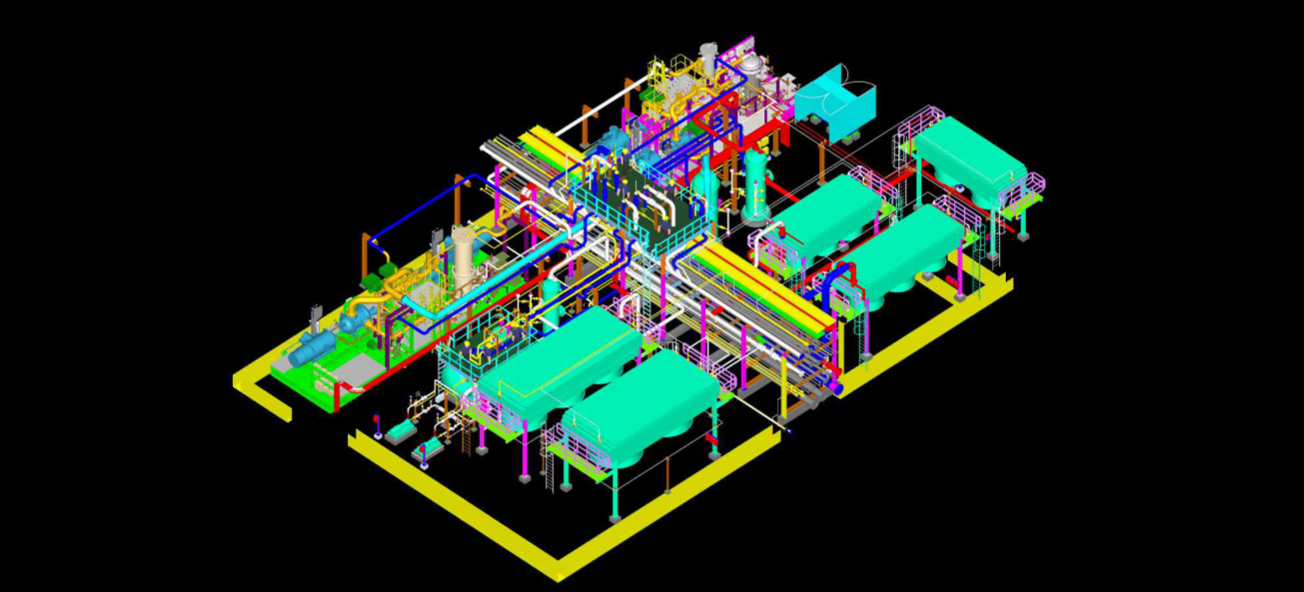

- 3D modelling was used to create a virtual representation of the components and their installation.

- Project management oversaw the entire process.

- A local site survey was conducted to assess the site's suitability for the project.

- Design and layout were completed to ensure optimal component arrangement.

- Basic and detailed engineering were conducted to ensure a safe and effective installation.

- Local Iraqi construction services were utilized for the installation process.

- Procurement was used to ensure the necessary components were acquired.

- Cost and scheduling were managed to ensure the project was completed within budget and on time.

- Quality assurance and quality control were used to ensure the project was completed to a high standard.

The project was completed on time and within budget and met all the safety and quality standards. We would like to thank our team and the client for their hard work and cooperation throughout the project.