...

...

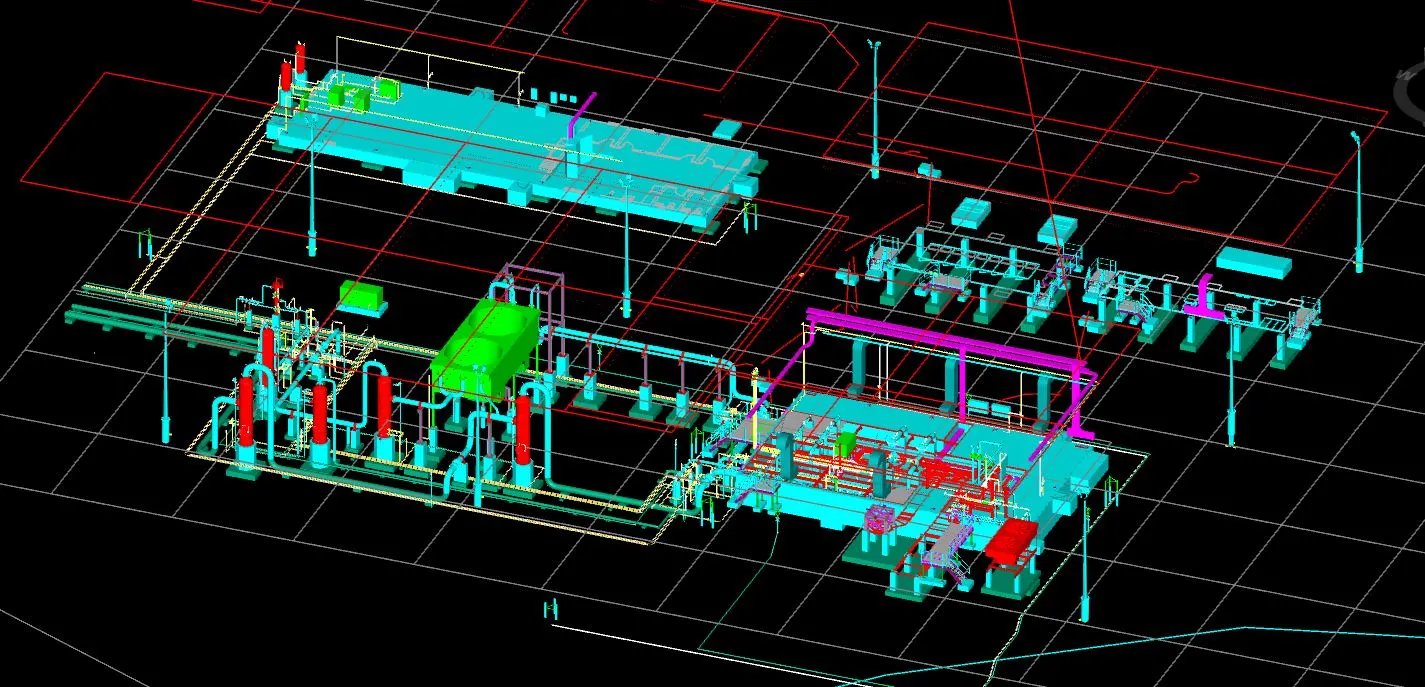

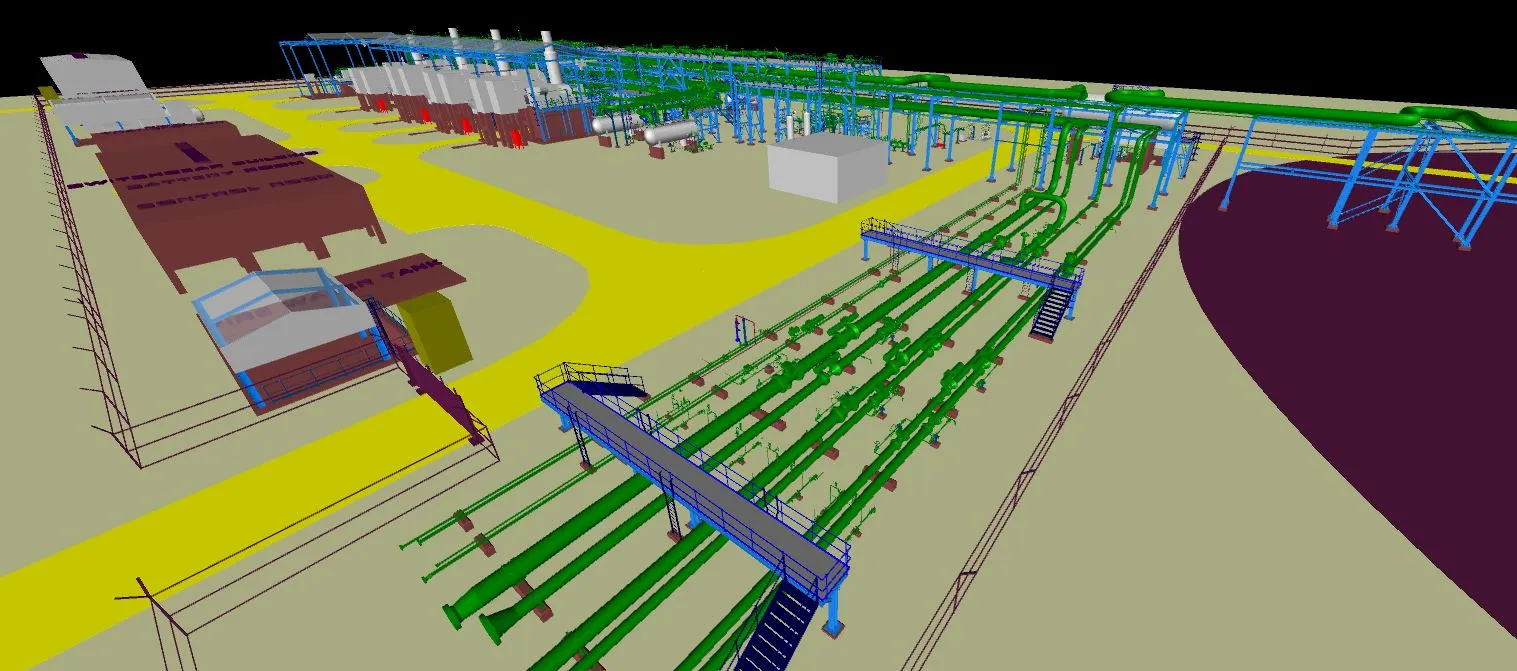

This project involved the full scope of Engineering, Procurement, and

Construction (EPC) management for the design and supply of a multi-stage

gas compressor system. This system consisted of three stages of

compression, namely the low-pressure (LP), medium-pressure (MP), and

high-pressure (HP) stages. In addition, the project included other

mechanical equipment packages that consisted of pressure vessels, pump

skids, heat exchangers, flare packages for both the LP and HP stages,

structural sheds, fire-fighting systems, and a seal gas compressor with a

sorbent type H2S removal unit. Electrical and instrumentation auxiliaries

were also included in the project, such as switchgears, distribution

panels, transformers, field instruments, junction boxes, cables, and

accessories.

To successfully complete this project, the following activities were undertaken:

- Detailed engineering for the compressor system and auxiliary equipment was conducted to ensure efficient operation and compliance with safety regulations and industry standards.

- Procurement activities were performed to ensure the timely and cost-effective acquisition of equipment and materials required for the project.

- Construction management was executed to ensure the successful installation and commissioning of the compressor system and auxiliary equipment.

- Electrical and instrumentation installation was completed to ensure the proper functioning of the compressor system and auxiliary equipment.

- Quality control was implemented throughout the project to ensure that all components were of the required standard and that the project met or exceeded industry and safety standards.

The successful completion of this project required careful planning, efficient execution, and effective communication between all stakeholders involved. The end result is a high-quality, reliable gas compressor system and auxiliary equipment that will serve the intended purpose for years to come.